-

High efficiency reduction

-

energy-saving design

-

Safe and harmless

-

Economic saving

-

Smart operation

hot water, saturated steam, high temperature flue gas, etc

Provide you with intelligent sludge treatment solution provider

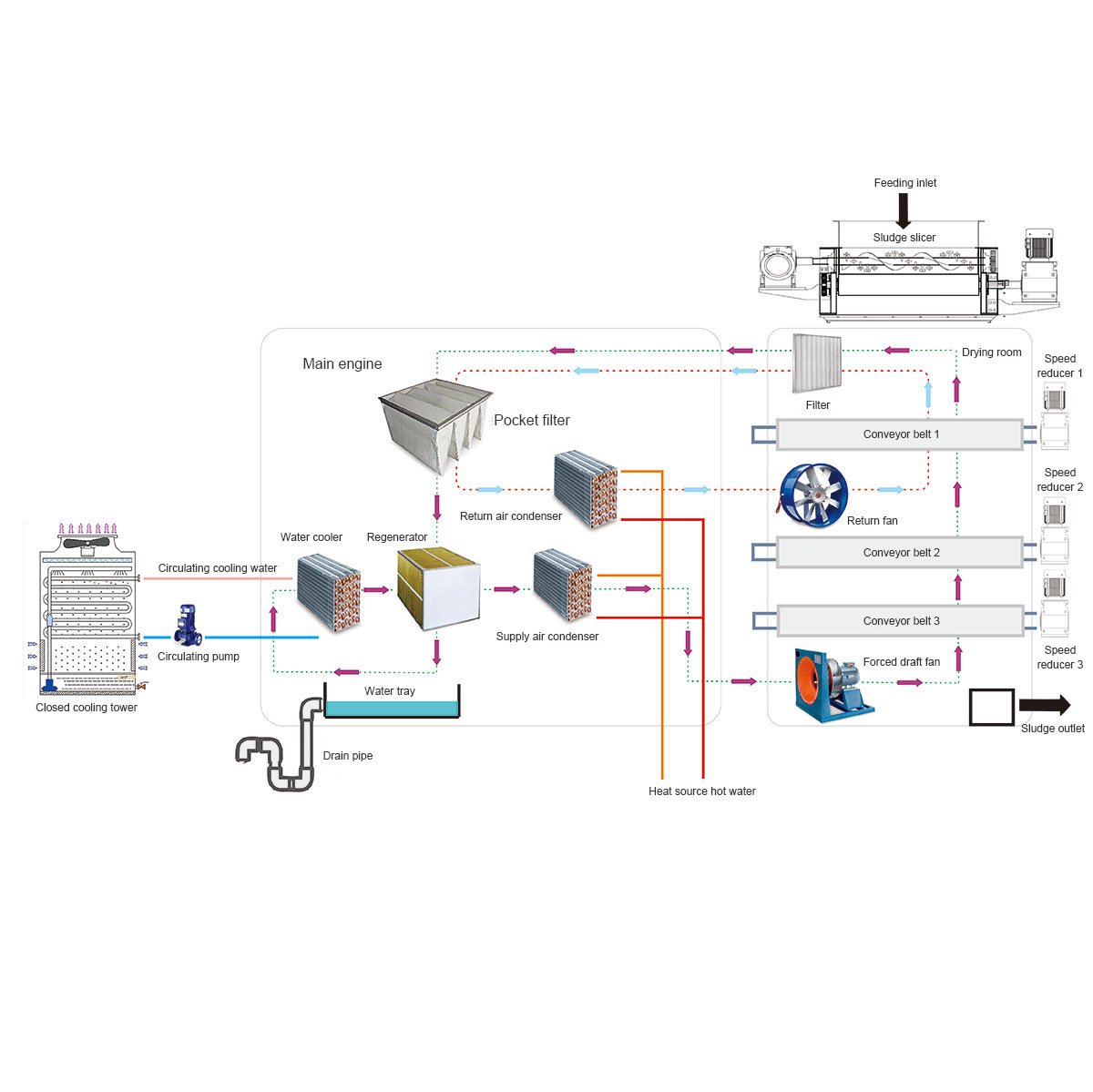

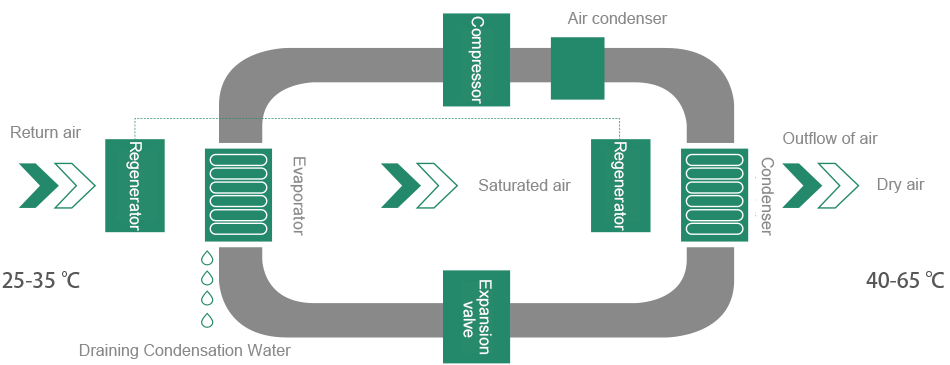

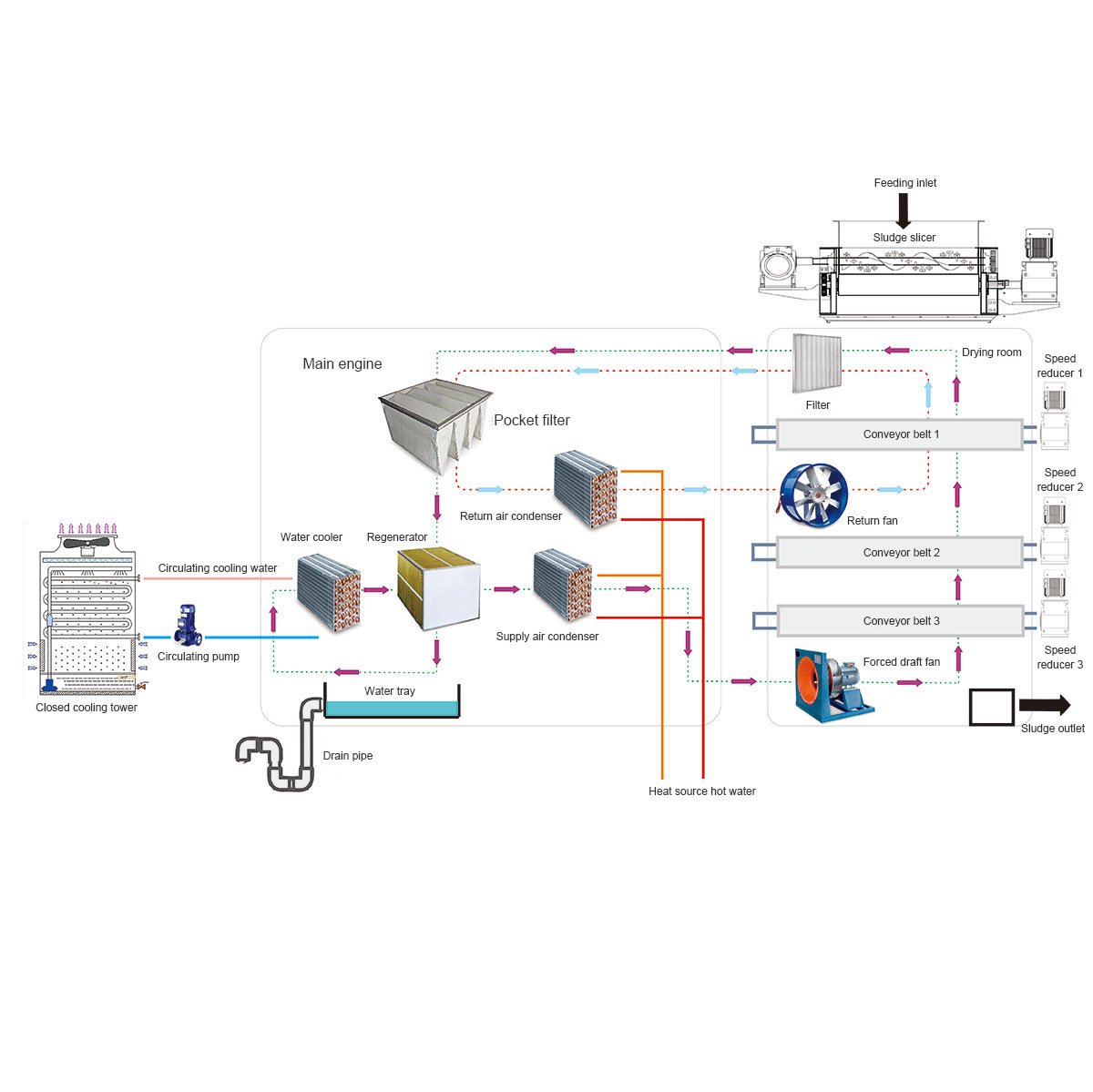

The unit uses the company's five core technologies: humidity gradient, uniform air flow in drying room, counter current drying, fully closed independent air duct, and nano electrophoresis anti-corrosion technology for heat exchanger. The comprehensive effect of the five core technologies is remarkable, with low temperature energy saving, small air volume, fast drying, and the highest energy efficiency of the whole unit is more than 4.0. The compressor adopts the scroll compressor of international famous brand for totally enclosed heat pump. The whole machine is of standard modular design with small floor area and flexible installation.

Perfect combination of dehumidification system + energy recovery + closed cycle combination

hot water, saturated steam, high temperature flue gas, etc

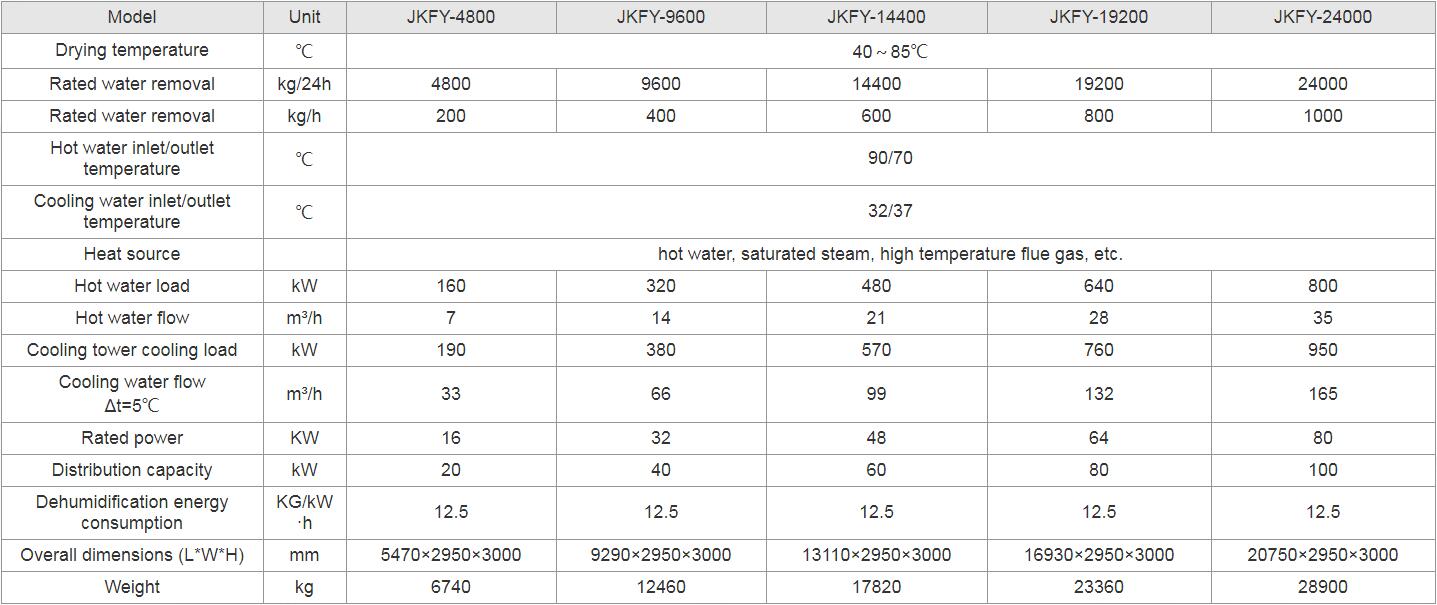

| Model | Unit | JKFY-4800 | JKFY-9600 | JKFY-14400 | JKFY-19200 | JKFY-24000 |

| Drying temperature | ℃ | 40~85℃ | ||||

| Rated water removal | kg/24h | 4800 | 9600 | 14400 | 19200 | 24000 |

| Rated water removal | kg/h | 200 | 400 | 600 | 800 | 1000 |

| Hot water inlet/outlet temperature | ℃ | 90/70 | ||||

| Cooling water inlet/outlet temperature | ℃ | 32/37 | ||||

| Heat source | hot water, saturated steam, high temperature flue gas, etc. | |||||

| Hot water load | kW | 160 | 320 | 480 | 640 | 800 |

| Hot water flow | m³/h | 7 | 14 | 21 | 28 | 35 |

| Cooling tower cooling load | kW | 190 | 380 | 570 | 760 | 950 |

| Cooling water flowΔt=5℃ | m³/h | 33 | 66 | 99 | 132 | 165 |

| Rated power | KW | 16 | 32 | 48 | 64 | 80 |

| Distribution capacity | kW | 20 | 40 | 60 | 80 | 100 |

| Dehumidification energy consumption | KG/kW·h | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 |

| Overall dimensions (L*W*H) | mm | 5470×2950×3000 | 9290×2950×3000 | 13110×2950×3000 | 16930×2950×3000 | 20750×2950×3000 |

| Weight | kg | 6740 | 12460 | 17820 | 23360 | 28900 |

1、Standard water removal tons: 65% moisture content of incoming mud, 25% moisture content of outlet mud, and the number of water tons that can be removed.;★Due to different sludge properties and moisture content, the difference of drying cycle is different.

Application

MON-SUN 8:30-17:30

+86-400-8080-920

Wechat OA

COPYRIGHT © 2021 Guangdong Jikang Environmental System Technology Co., Ltd | Copyright statement

Official account