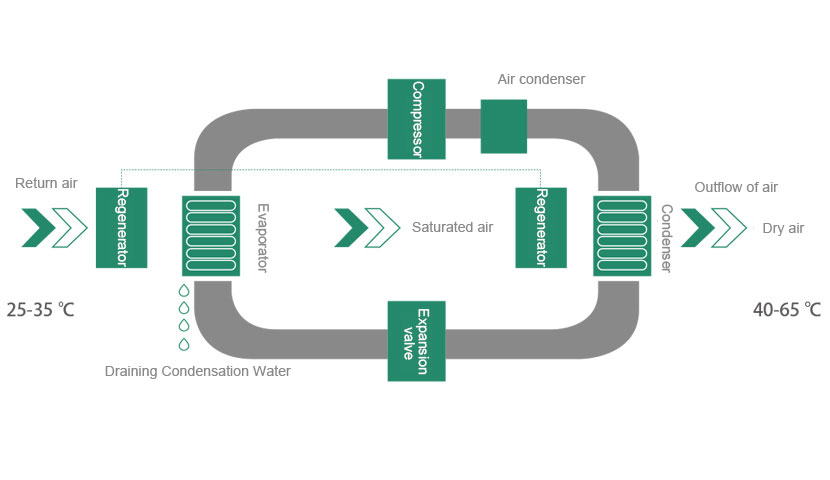

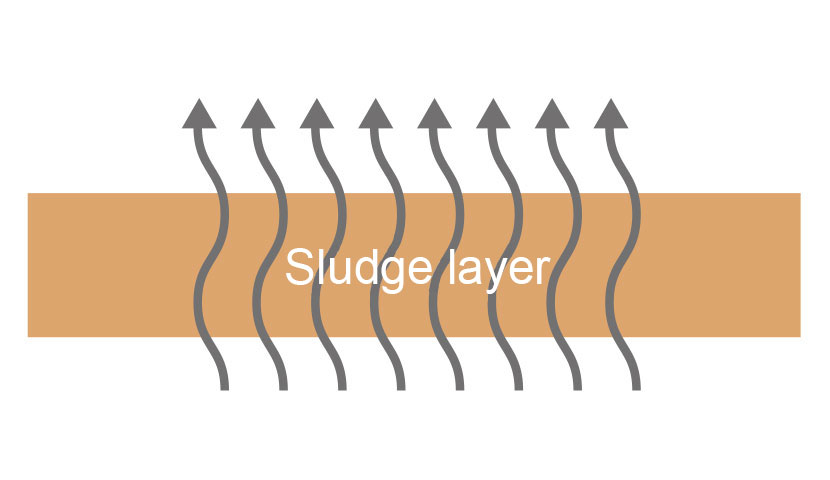

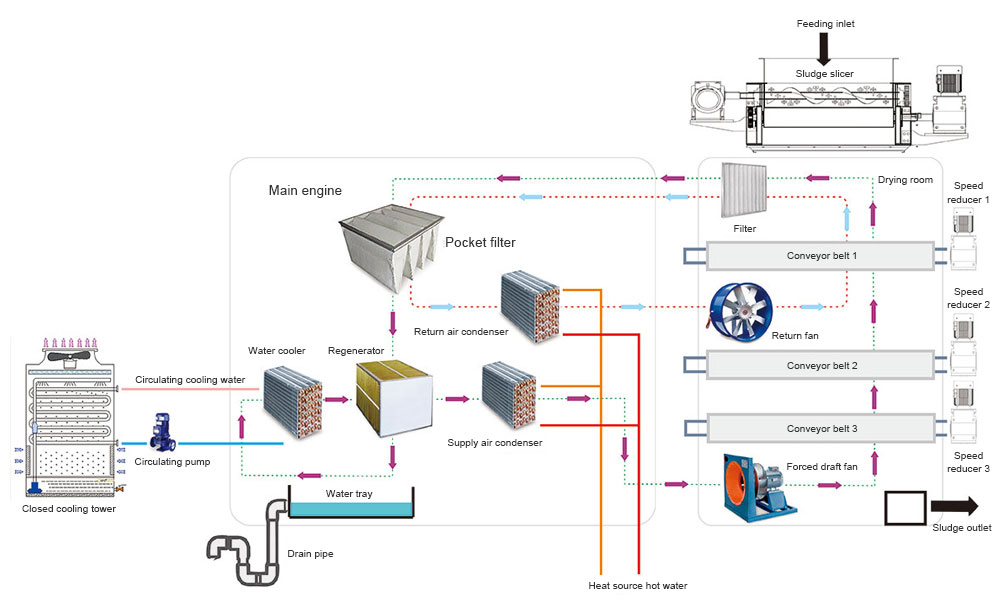

Through the joint action of high temperature heat source and dehumidification cold source, 40 ~ 60 ℃ extremely dry air is produced, which penetrates the sludge dynamic transmission network belt to evaporate the sludge moisture, creating a low-temperature and energy-saving drying environment; after absorbing water, the air returns to the dehumidification cold source and condenses low-temperature liquid water for discharge through the economic closed cycle.

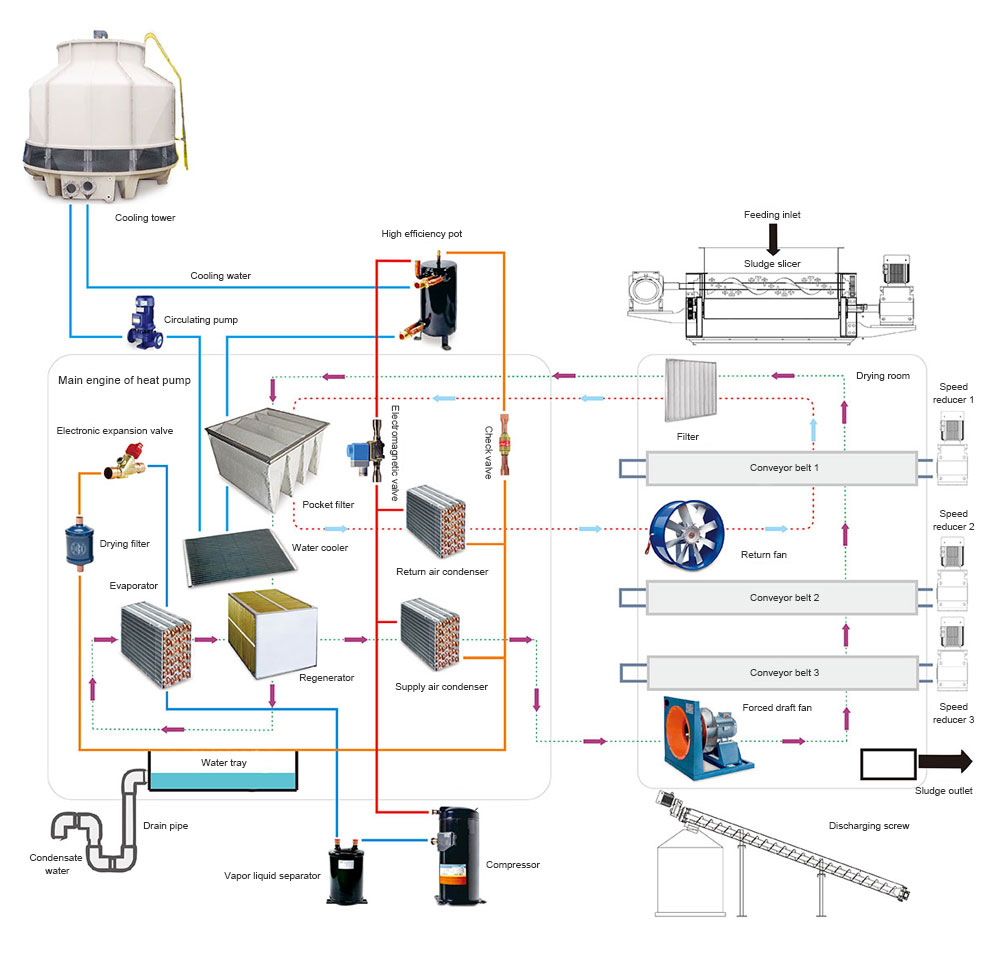

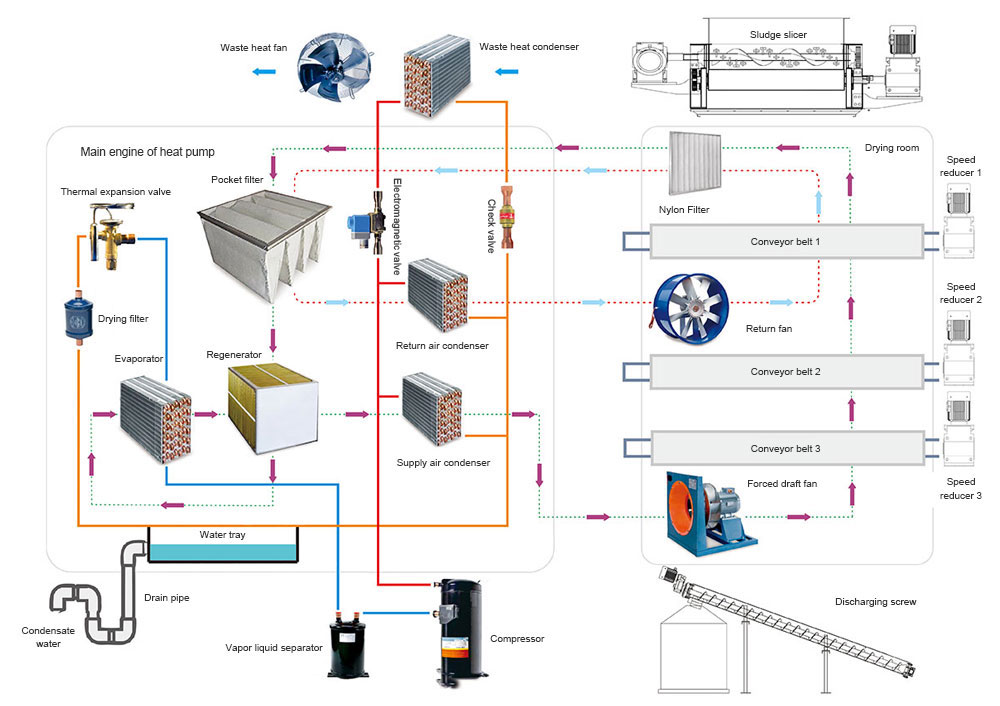

According to energy, low temperature drying equipment can be divided into two types: low temperature drying of electric sludge and low temperature drying of waste heat sludge. The low-temperature drying of electric sludge mainly uses the compressor as the power source to provide high-temperature heat source and dehumidification cold source, while the low-temperature drying of waste heat sludge mainly uses the steam or high-temperature hot water generated by the existing waste heat as the high STX temperature heat source, and the cooling water or sewage from the existing cooling tower as the dehumidification cold source. Compared with the traditional heat drying method, the low-temperature drying equipment is more efficient and energy-saving, without additional waste gas and dust treatment.